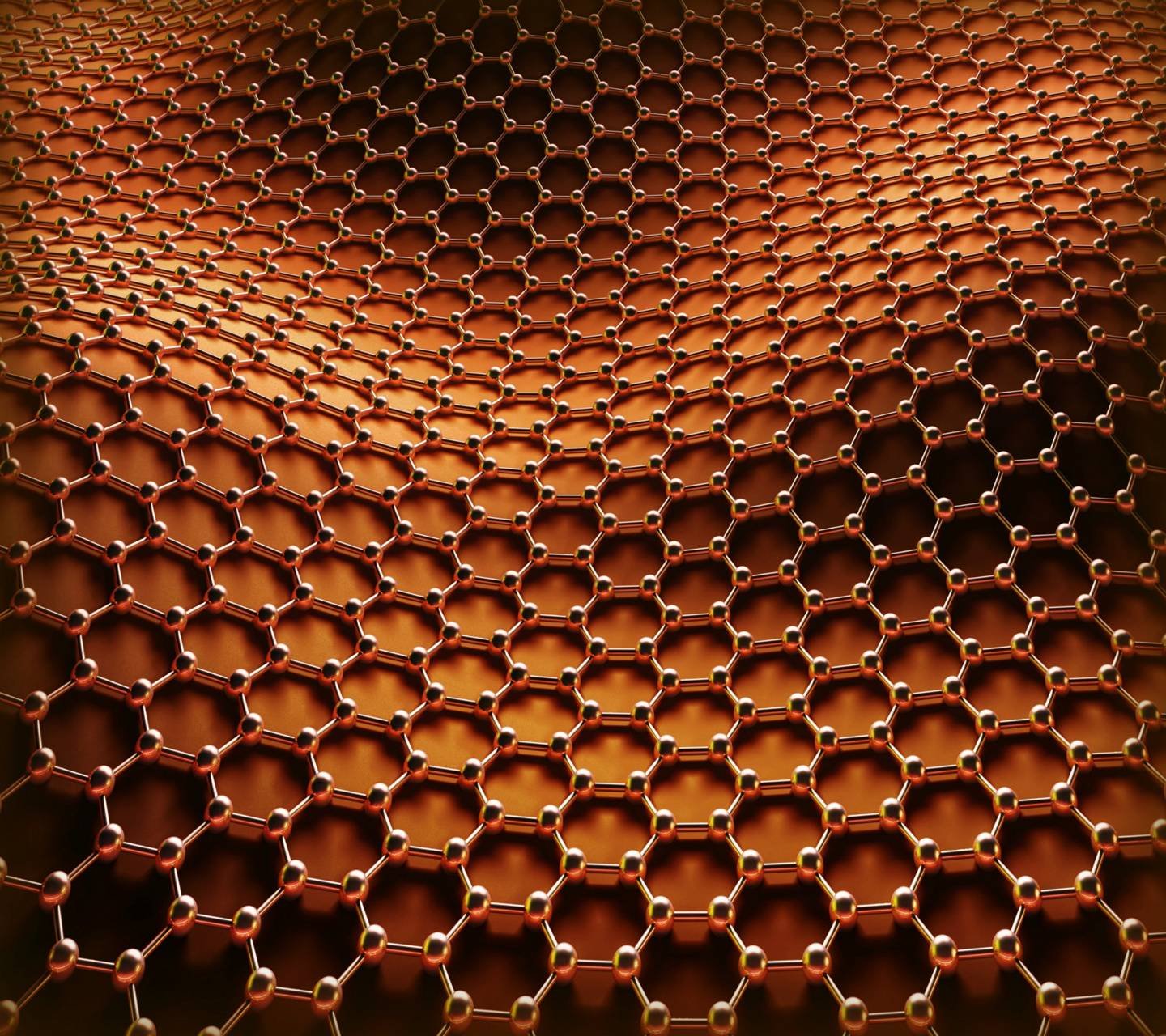

Scaling-up SuperLubricity into Persistence

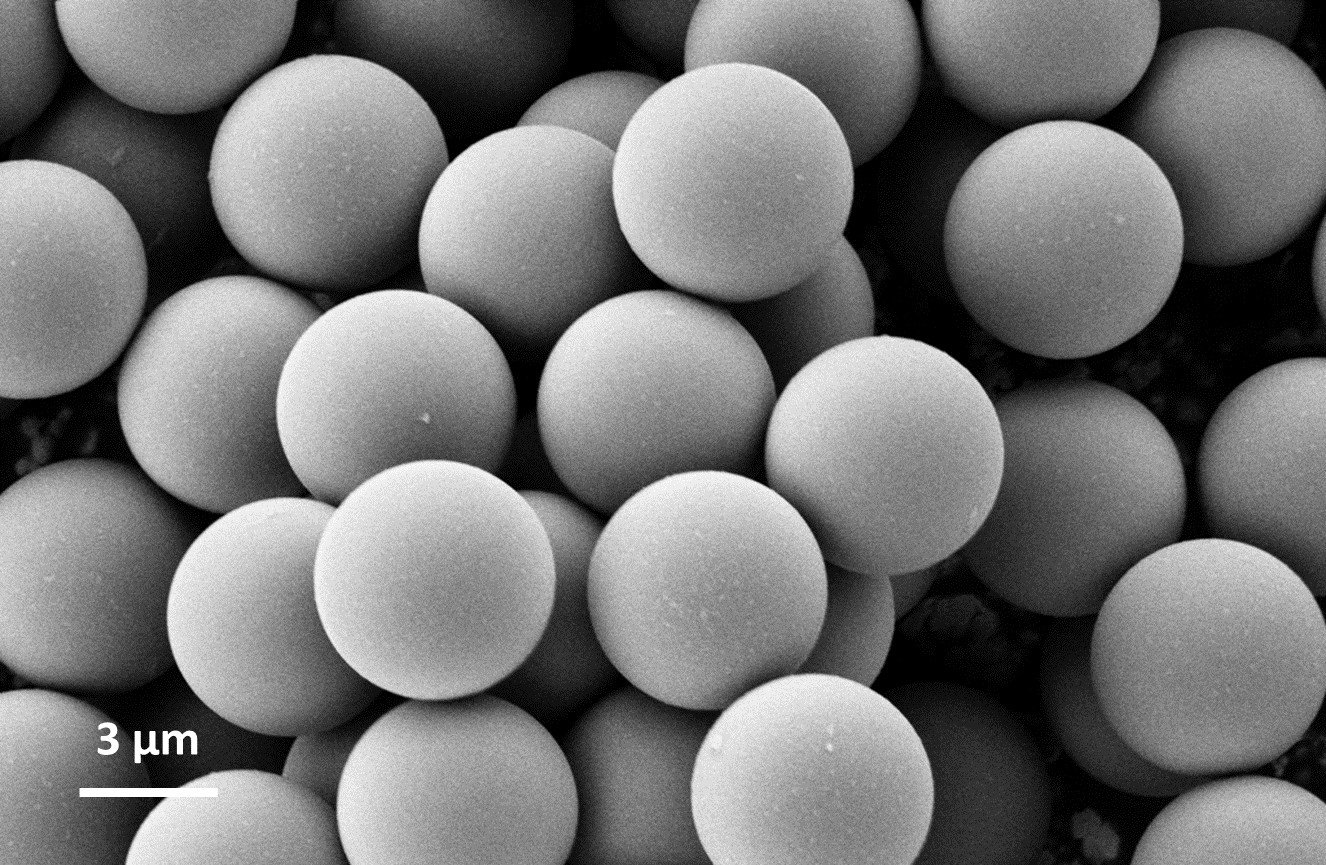

We aim to replicate superlubricity across length scales, transforming it from an atomic-scale lab curiosity to a manufacturing-scale technology that overcomes the severe friction of boundary lubrication

Connect with us

Interested in how our products and services can benefit you? Fill out our contact form—we’d be happy to connect and explore how we can help.

About Us

Industry Opportunities

We partner with industry leaders to integrate advanced lubrication solutions. Interested in collaborating? Let’s connect.

Our Consortium

We collaborate across a network of seven partners, with active research hubs in Ireland, Germany, Norway, the Netherlands, France, and Ukraine.

Early Career Researchers

Our research is made possible by the dedication and expertise of our talented PhD students and Postdoctoral Researchers.